The Dunlop process and the Talalay process are the two major methods for producing latex foam. There is a lot of information (and misconceptions) on the distinctions between these two types of foam available online.

Natural latex is a liquid substance derived from the rubber tree (Hevea Brasiliensis), the majority of which is grown in Southeast Asia. The liquid is collected from the tree and treated with ammonia and TMTD/ZnO to retain its characteristics.

This standardized LA-latex (low-ammonia latex) is utilized as a raw material in the manufacture of balloons, gloves, sanitary items, and other latex foam goods such as a Dunlop latex mattress and pillows.

The Origin Of the Dunlop Method:

John Boyd Dunlop (1840–1921), a Scotsman, created the first inflated tire for his son’s tricycle in 1887, based on the heat vulcanization of natural rubber, and patented it on December 7, 1888.

However, his patent was declared invalid two years later because another Scottish inventor, Robert William Thomson (1822-1873), had already patented the identical invention in the United Kingdom, France (1846), and the United States (1847).

Regardless, the technique was named after Dunlop and quickly became the standard method for vulcanizing rubber and latex foam products.

The DUNLOP and TALALAY techniques have established industrial standards:

Currently, there are two standard ways for producing latex foam items: the DUNLOP and TALALAY processes. The TALALAY method, invented in the late 1940s, takes longer and is more complicated than the DUNLOP process.

This method is only utilized by a few producers throughout the world and has a tiny market share. Natural latex (NL) or SBR-latex (styrene-butadiene-rubber) or mixes of both are the primary raw ingredients in both systems.

What is the Dunlop Method?

When using pure natural latex, the latex “milk” is combined with the necessary ingredients.

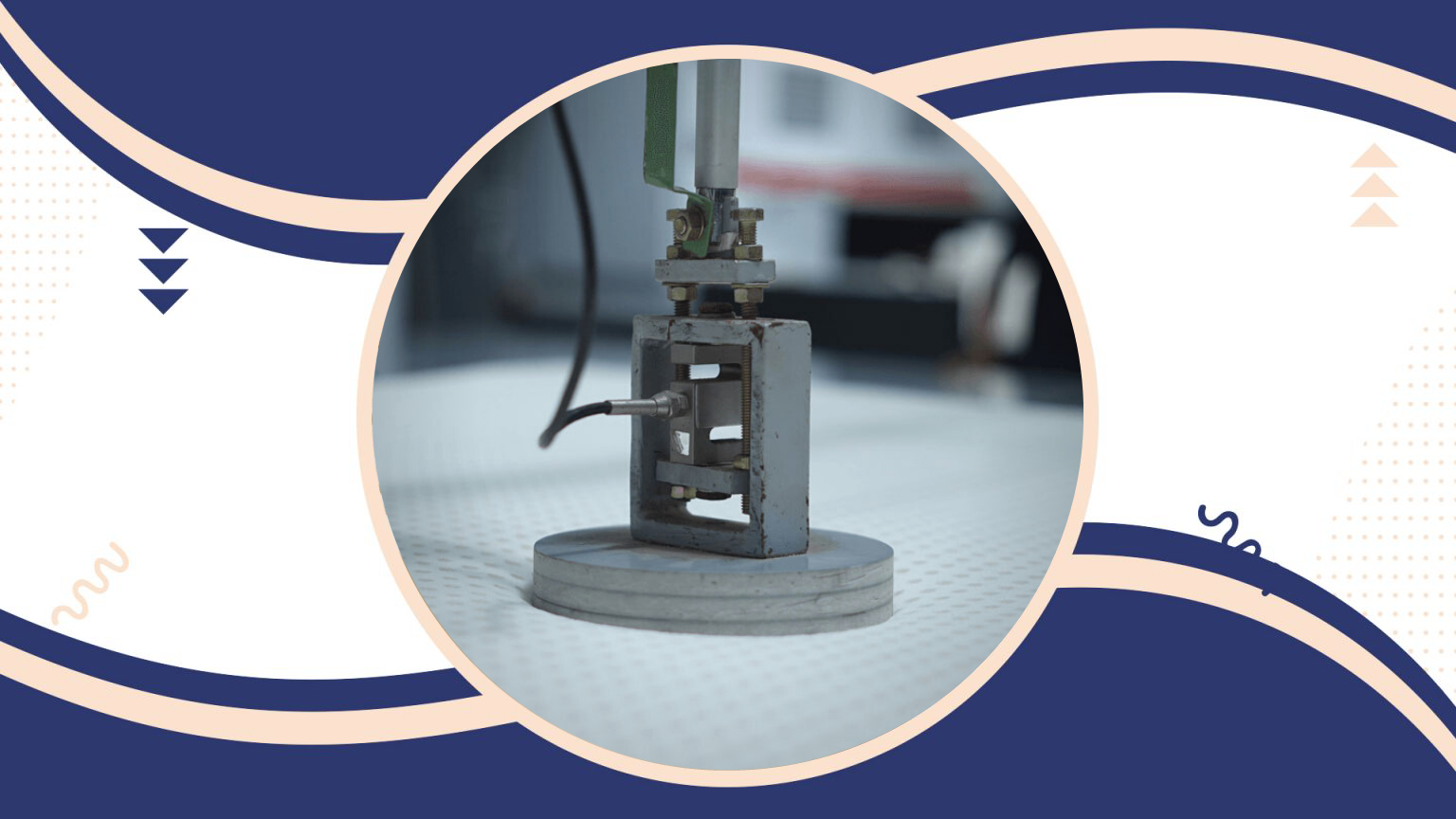

When the compound has matured, it is foamed up using a mechanical mixer (SBR-latex can be foamed up without maturing) and poured into metal molds. To create a rapid response that stabilizes the foam structure, a gelling agent is added to the mixture.

After that, the molds are placed in a steam oven or tunnel to vulcanize the cores. Because foamed goods are excellent thermal insulators, the molds are outfitted with a plethora of pins to transmit heat into the foam itself.

After being vulcanized, the pillow or mattress core is stripped, cleaned, and dried before being sold.

Dunlop Latex Mattresses are made entirely of organic latex and come with certain certifications that suggest their organic nature.

Furthermore, The top layer of all organic latex mattresses is constructed of natural latex that is eco-INSTITUT and OEKO-TEX Standard 100 certified.

It is made of high-quality natural latex with built-in ergonomic support, allowing for greater air circulation and pressure point alleviation.

The ‘Novel’ Dunlop Process:

Because Radio Frequency technology does not rely on heat transfer, even thick, shaped, and dense latex foam items (mattress cores, anatomic pillows, etc.) can be quickly heated up and vulcanized: actually, Radio Frequency is instantly absorbed in a controlled amount (adjusted as required by the machine itself) by the water.

Thus, heating the foam and fully vulcanizing it takes just a few minutes, both in the middle and on the surface.

Molds can be built of lightweight, low-cost composite materials that enable weight reductions of up to 60% as compared to typical metal molds: the reduced mold mass adds considerably to lower energy usage.

Furthermore, the use of proper mold materials allows for the easy and rapid stripping of vulcanized objects. Last but not least, mold design is more adaptable since it is not restricted by the presence of pins.

What about drying latex foam after vulcanization, cleaning, and squeezing?

The same technological factors that make Radio Frequency more efficient and cost-effective than traditional steam-based vulcanization processes apply to the final drying phase of latex foam products after washing and squeezing.

Morning Owl employs Dunlop latex in all customized organic mattresses from a source that has gone above and above to get not just its rubber tree growth but also latex processing certified organic.

The genuine Dunlop latex is also GOLS (Global Organic Latex) certified.

Dunlop Latex Mattresses provide Support that is both comfortable and adaptable:

Dunlop yields beneath the body but is not “bouncy.” It’s perfect for those who require a comfy, dependable sleeping surface. People suffering from nerve-related back discomfort enjoy Dunlop’s continuous, reliable assistance.

Softer Dunlop layers at the top of a mattress can provide gentle cushioning, while medium and/or firm layers beneath can provide as much support as needed. Dunlop is less costly than Talalay since it is less processed.

This makes it a popular choice for a variety of applications, such as mattresses for youngsters, visitors, or anybody who wishes to avoid a pillowy or “sinking” mattress sensation.

Why should you choose a Dunlop Latex Mattress?

- Morning Owl’s Latex’s excellent cushioning and durable support play an important role in back pain relief. The medium firm layer comfortably cradles heavier body regions, while mild contouring relieves pressure at joints and the lower back.

- Bedroom allergens create a dangerous sleeping environment, therefore frequent cleaning is essential. But not if you get our Morning Owl Medium Firm Natural Latex Mattress, which is naturally antimicrobial and repels mold, mildew, and dust mites.

- Our natural latex’s open-cell structure lets air flow through continually, which improves breathability. Our mattress doesn’t use chemicals, which is why it does not retain body heat and keeps you cool and dry.

- This mattress is intended to be enjoyed by people of all ages, from children to the elderly. Also, it is suitable for all sorts of sleepers, including side, front, and back sleepers, since it distributes weight equally regardless of your sleeping pattern.

- Whether your partner or your kid tosses and turns a lot at night, our natural latex is sensitive enough to reduce motion transfer by absorbing it, resulting in a night of restful sleep.