But Before that let’s find out what Latex is!

Latex is a natural milky liquid material which is extracted from the sap of the rubber tree, Hevea Brasiliensis. This milky liquid latex is then processed and made into comfortable solid latex foam which is used in latex mattress manufacturing.

How Latex India’s Best Certified Natural Latex Mattress Manufacturer

Complete Journey of Latex Mattress Manufacturing

RUBBER FORESTS OF KERALA

Our story starts in the forests of Kerala, India, where rubber trees thrive and are found in abundance. Our mattress factory, which is situated in Kottayam, Kerala, is also surrounded by vast rubber forests. The latex used in our mattresses and pillows are tapped from these forests which is spread across most of Kerala.

LATEX TAPPING

The process of drawing liquid latex from the soft barks of rubber trees is called ‘latex tapping’. Deep grooves are made in the soft bark with hooked knives. We are careful not to make them in a way that harms the growth of the tree. The liquid then oozes out of these grooves. At the end of the groove, we place a container to collect the liquid latex The process of tapping can be cut short when the oozing halts, which can often happen within six hours. However, the beauty of these trees is that we can immediately make new cuts in their barks to access their bounty once again.

Don’t worry; no trees are harmed during the process. Interestingly, the sap in the rubber trees gets replenished quickly. Also tapping rubber trees for their liquid must be done when there is no direct sunlight. Sunlight can cause the collected latex to turn hard. Hence, tapping is always carried out at night or in the wee hours of the morning.

What more? The trees actually reduce carbon dioxide in the air by a huge margin. Hence, cultivating them is a huge boon!

DO YOU

KNOW ??

TAPPING ALMOST TWELVE ACRES OF RUBBER TREES FOR A WHOLE DAY WOULD YIELD JUST ENOUGH LATEX TO MAKE ONE QUEEN-SIZED LATEX MATTRESS

LIQUID LATEX SHIPPING

The liquid latex that is collected is shipped, immediately on the same day, to our latex processing plant. This helps us in keeping the liquid fresh and in avoiding coagulation. After all, we manufacture only the best for our customers.

LATEX PROCESSING

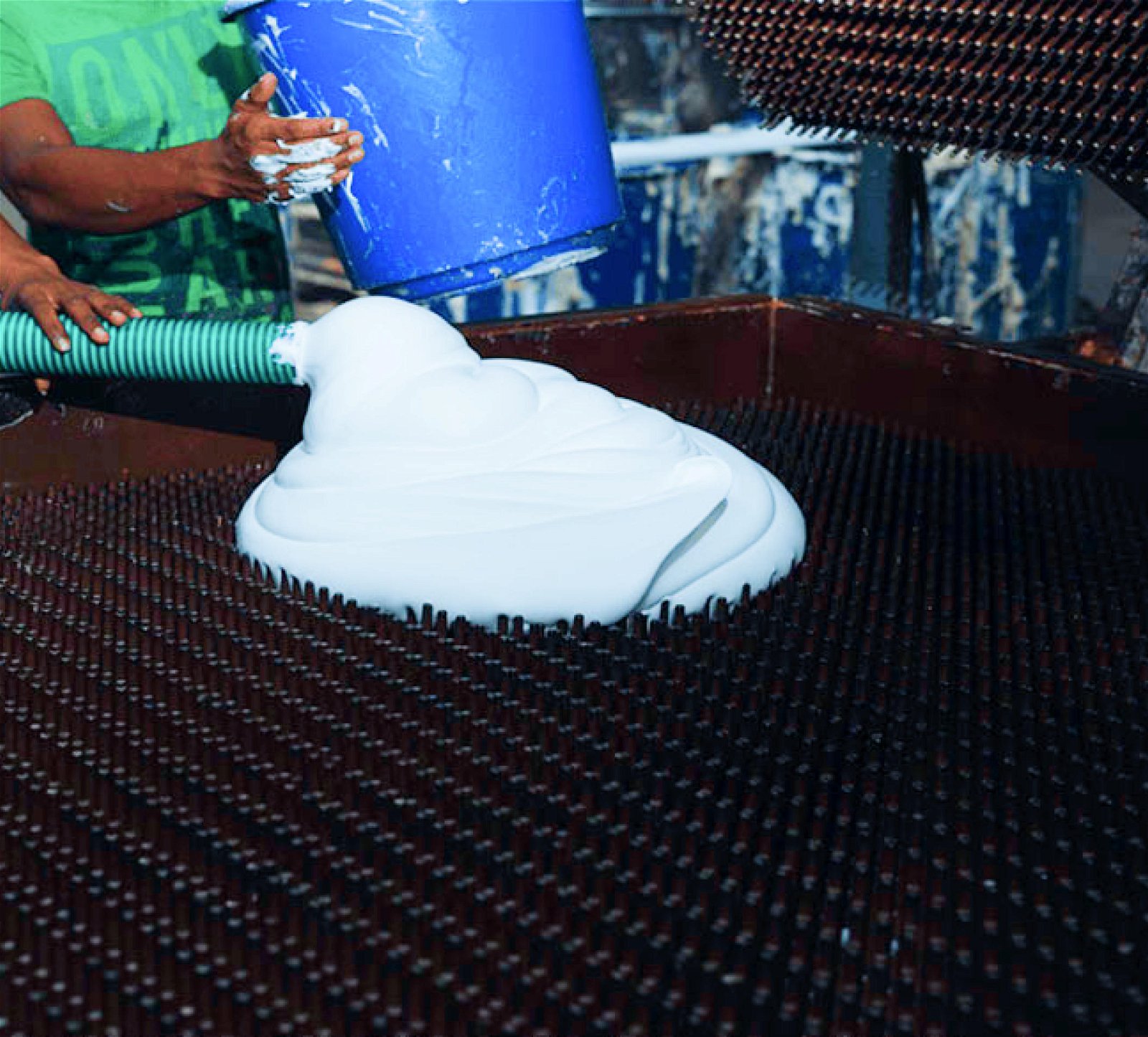

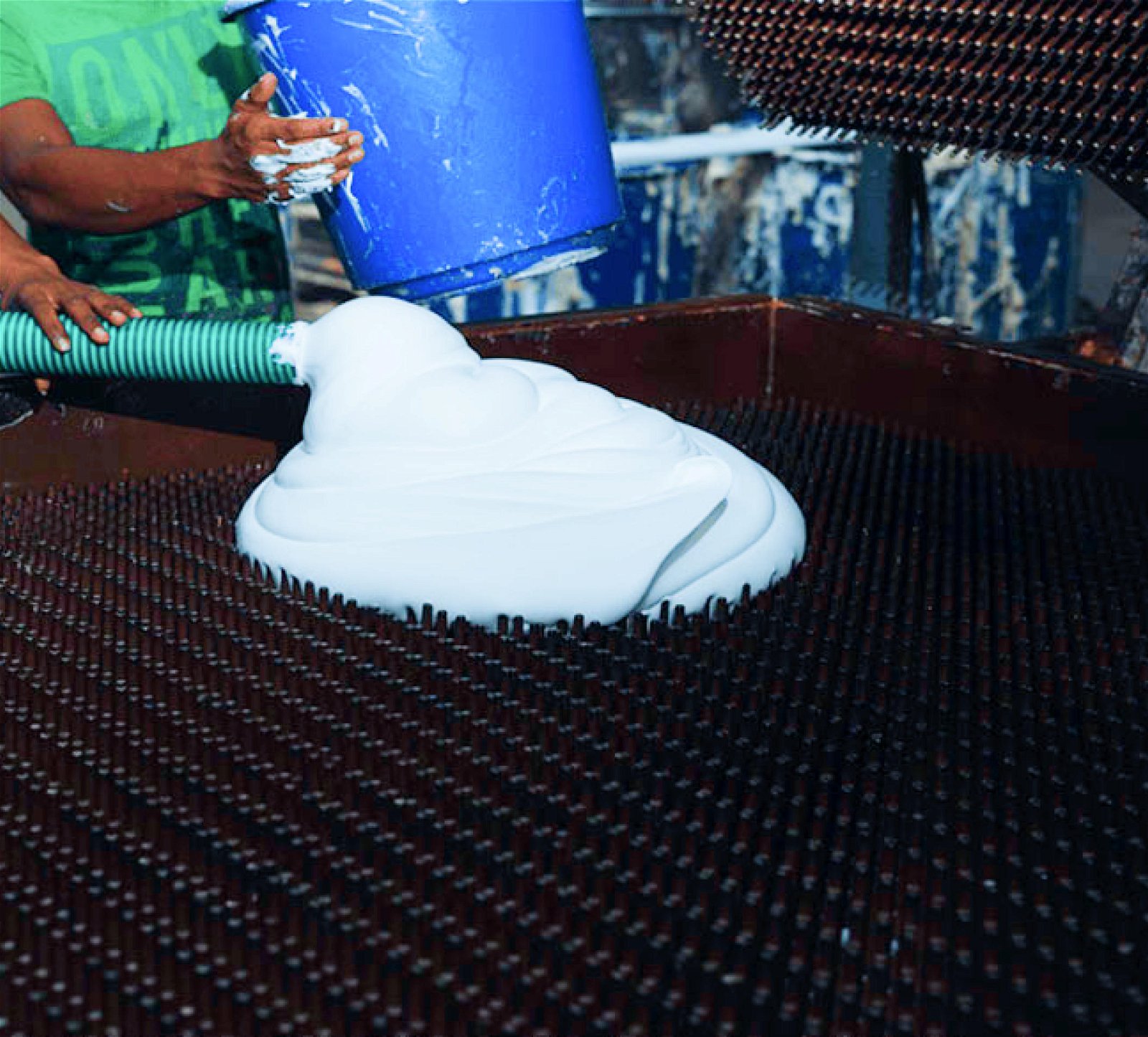

At the latex processing plant, liquid latex is sieved into large tanks. This ensures that the latex is free of particulate matter or coagulations. These tanks act like industrial-strength blenders. They whip the latex into a viscous foamy paste. We use a complete organic process called the Dunlop method, which can be traced back to at least a century. It is considered the oldest latex mattress manufacturing process.

SOLID LATEX FOAM

CREATION

Now it is time to use the moulds! The latex foam paste from the previous step is poured into special moulds. The vulcanization process follows, which consists of the moulds being sealed and heated. This process ensures that latex gets the right balance between firmness and softness. The pin core technology used helps create an opportunity for healthy air to flow through the mattress.

Once the latex is removed from the mould, we spray water to cool and clean the mattress. Then we bake it in a special oven to ensure there is no extra moisture. The end product is firm yet soft, comfortable, and just in the right texture for you.

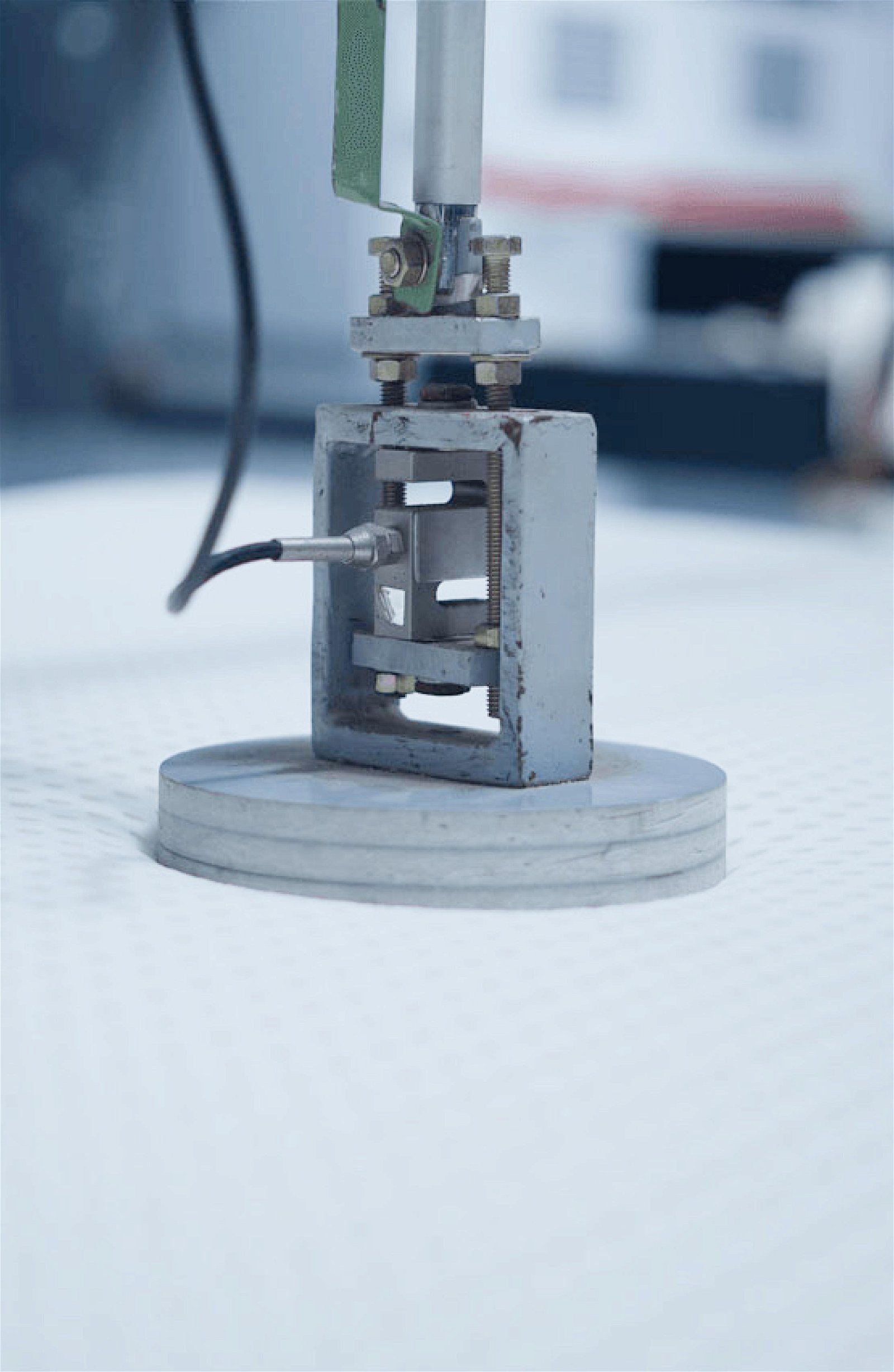

LATEX FOAM QUALITY CHECKS

We are committed to shipping out great quality products for all our customers. We regularly undertake manual and computerised testing of the each mattress that we produce. We compress different parts of each mattress and feed the data into our computers this ensures that only those with an acceptable & pleasant level of stiffness make it through the quality inspection.

Testing for durability is equally important for us. We take one mattress per batch and place it in a barrel. This rotates for several times, to reproduce the conditions of someone lying on the mattress. In this way, the barrel rotations are mimicking the movements of someone moving around on the mattress. This goes on for hours and hours. The number of rotations before the mattress begins to deteriorate gives us a clear picture of its durability and thus the durability of all the mattresses in that batch.

NATURAL LATEX RUBBER FOAM CERTIFICATIONS

Morning owl latex rubber foams are Eco-INSTITUT and OEKO-TEX Standard 100 Certified Natural. Rest assured, with us, you and your family are not exposed to any unsafe surface.

Eco-INSTITUT Certification

Eco-INSTITUT certification is given by the Eco Institute which is a renowned and approved testing laboratory located in Cologne, Germany. This institute tests bedding products to detect and evaluate the presence of pollutants, odors, toxins, and emissions. The Eco-INSTITUT analyses and inspects the quality of the content present in a wide range of manufactured products. They even test for emissions from the product. Once the product passes all the required tests, the certificate is issued.

Eco-INSTITUT is a world renowned body and their certificates are considered as a testimonial for pollutant and harmful chemical free products. They give confidence to the consumers that they are investing in something that is totally safe for them.

OEKO-TEX Standard 100 Certified

The OEKO-TEX Standard 100 certification helps consumers make more informed purchasing decisions. OEKO-TEX consists of 18 independent research and test institutes to detect the existence of harmful chemicals such as lead, arsenic, etc. along with vocs, pesticides, dyes, phthalates, etc. Some other materials that are tested at OEKO-TEX are heavy metals, chlorinated phenols, formaldehyde, chloro-organic carriers and products with low ph.

Morning owl natural latex rubber foam has successfully attained OEKO-TEX certification our products are annually tested to ensure this certification is active all the time.

OEKO-TEX Standard 100 Certified

OEKO-TEX Standard 100 certification helps consumers make more informed purchasing decisions. OEKO-TEX consists of 18 independent research and test institutes to detect the existence of harmful chemicals such as lead, arsenic, etc. along with vocs, pesticides, dyes, phthalates, etc. Some other materials that are tested at OEKO-TEX are heavy metals, chlorinated phenols, formaldehyde, chloro-organic carriers and products with low ph.

Morning owl natural latex rubber foam has successfully attained OEKO-TEX certification our products are annually tested to ensure this certification is active all the time.

FREE MATRESS SHIPPING TO CUSTOMERS

We offer free standard delivery across India for all our mattress and pillow orders. Your order gets freshly prepared and dispatched within 3-5 days from the day of your order. Our delivery partners then deliver the products to your door step in another 5-7 days. Total delivery time is between 10-12 days.

Your purchase also helps the environment as it supports the growth of rubber tree plantations, which removes tons of carbon dioxide from the air. It also provides jobs for the rubber tappers in the tropical areas where employment opportunities are often scarce.